NOAA Manual NOS NGS 1

Geodetic Bench Marks

U.S. DEPARTMENT OF COMMERCE

National Oceanic and Atmospheric Administration

National Ocean Survey, Rockville Md.

Lt. Richard P. Floyd

|

September 1978 |

|

Jump to TABLE

OF CONTENTS

Note: This file was generated by OCR scan from

a paper copy. As such:

- Obsolete information is unaltered to preserve the original 1978 text.

- Some additional inadvertent transcription error may exist.

- See the PDF version for a more authoritative source.

Jump to TABLE

OF CONTENTS

|

|

|

|

|

|

NOAA Manual NOS NGS 1

Geodetic Bench Marks

Lt. Richard P. Floyd

NOAA Corps

National Geodetic Survey

Rockville, Md.

September 1978

U.S. DEPARTMENT OF COMMERCE

Juanita M.Kreps, Secretary

National Oceanic and Atmospheric Administration

Richard A. Frank, Administrator

National Ocean Survey

Allen L. Powell, Director

For sale by the Superintendent of Documents, U.S. Government Printing Office

Washington, D.C. 20402

Stock Number 003-017-00442-2

|

FOREWORD

Bench marks are long lasting points for which elevations have been determined,

used to control other surveys and to monitor movement of and within the

Earth's crust. They constitute the visual evidence of vertical control established

by the National Geodetic Survey (NGS), an office of the National Ocean Survey,

National Oceanic and Atmospheric Administration. Bench mark design and

setting procedures are important to the leveling program. In the past, however,

availability of materials and ease of setting were often the primary considerations

rather than soil mechanics, geology, properties of materials, and the like.

Advancing technology brought both the ability to determine elevations

more precisely and a greater need for bench marks to hold these elevations. The

releveling program for the new adjustment of the National Vertical Control Network

provided an ideal opportunity to upgrade the quality of NGS bench marks

to meet future geodetic requirements.

This manual was written for two main groups of users. One includes managers

and field personnel, both publicly and privately employed, who are involved

with setting bench marks that will meet NGS specifications. The guidance

given here must be adhered to strictly to obtain the quality required by the

National Geodetic Survey. The other group consists of the users of NGS vertical

control data. Supplementing other vertical control data, the information in this

manual makes it possible to judge the reliability of an NGS bench mark

elevation.

Because of a limited number of bench mark types, it is not possible to set

the optimal monument in every case. For some installations, geologists or other

specialists might be consulted. The manual includes enough detail to enable

judicious modification in design when the occasion arises.

Dimensions have been given only in metric units wherever feasible. Commercial

products are normally specified in English units, and consequently,

English units are given in parenthesis when applicable. A conversion table from

metric to English units is given in appendix A.

ii

CONTENTS

| Chapter |

Page |

| Foreword |

iii |

| Abstract |

1 |

| 1. Introduction |

1 |

2. Sources of vertical instability

|

2 |

|

Origins in the subsurface |

2 |

|

On or near-surface origins |

3 |

|

Motion intrinsic to the monument |

5 |

|

Intended stability of NGS bench marks |

5 |

3. Considerations in selecting a site

|

5 |

|

Security |

5 |

|

Utility |

6 |

|

Stability |

6 |

|

Corrosive environment |

10 |

|

Safety |

12 |

| 4. Installation |

12 |

|

Maintaining good public relations |

12 |

|

Special considerations at line intersections |

13 |

|

Disk set in bedrock or structure |

13 |

|

Class A rod mark |

14 |

|

Class B rod mark |

25 |

|

Miscellaneous marks |

26 |

| 5. Descriptions |

35 |

| Appendix A. Approximate conversion table: metric to English

units |

36 |

| Appendix B. The use of geopotential heights for Great Lakes

Vertical Datum |

37 |

| Appendix C. Soils |

41 |

| Appendix D. Existing monumentation in the vertical network |

43 |

| Appendix E. Examples for determining bench mark depths |

45 |

| Bibliography |

48 |

| Index |

49 |

|

TABLES

|

| 1. Summary of measures taken to set high-quality bench marks |

11 |

| 2. Sleeve depth for class A rod mark set within the

continental United States |

27 |

| 3. Minimum depth for class B rod mark |

27 |

|

FIGURES

|

| 1. Referencing of bench marks |

7 |

| 2. Intersection of lines-of-position |

8 |

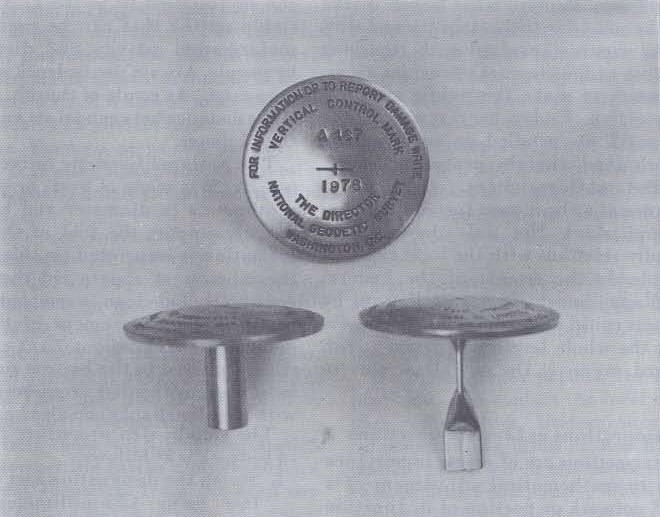

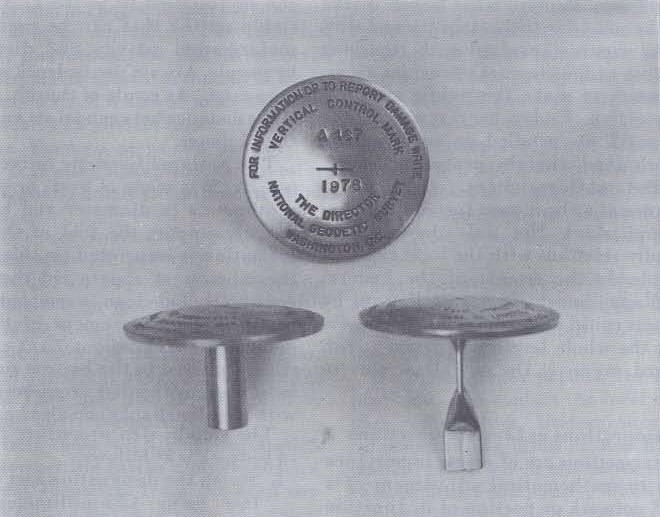

| 3. NGS bench mark disk stamped with designation and year |

14 |

| 4. Sleeved class A rod mark |

16 |

| 5. Class A rod mark showing logo flange and hinged access

cover |

17 |

iii

|

| 6. Setting a sleeved class A rod mark |

20 |

| 7. Distribution of potentially expansive materials, Northeastern States |

28 |

| 8. Distribution of potentially expansive materials, Southeastern States |

29 |

| 9. Distribution of potentially expansive materials, North-Central States |

30 |

| 10. Distribution of potentially expansive materials, South-Central States |

31 |

| 11. Distribution of potentially expansive materials, Western States |

32 |

| 12. Climate factor |

33 |

| 13. Extreme depth of frost penetration |

34 |

| 14. Mississippi River flows uphill |

38 |

| 15. Elevation |

38 |

| 16. Geodetic reference ellipsoid |

39 |

| 17. The geoid |

39 |

Mention of a commercial company or product does not constitute an endorsement

by the NOAA National Ocean Survey. Use for publicity or advertising

purposes of information from this publication concerning proprietary products

or the tests of such products is not authorized.

iv

GEODETIC BENCH MARKS

Lt. Richard P. Floyd

National Geodetic Survey

National Ocean Survey, NOAA

Rockville, Md. 20852

| ABSTRACT.-Geodetic survey control points must be remarkably stable due to

the very intent of establishing geodetic control. All monuments are subject to

the effects of geologic and soil activity. Vertical control points are particularly

vulnerable because this activity results in vertical movements much more so

than horizontal motion. In addition to natural disturbances, damage inflicted

by mankind is a critical problem in monumentation. This manual explains how

and where to set bench marks for maximum stability and calls attention to the

factors that affect vertical instability. |

1. INTRODUCTION

To function as good references for elevations,

bench marks must be relatively stable points. Accordingly,

it is necessary to define what is meant

by stability before an understanding of high quality

monumentation can be gained. "Stability"

refers to the ability to maintain a fixed position.

It is characterized by its degree and duration.

To the local surveyor running a topographic

survey on a small construction site, a stable point

could be defined as the top of a prominent boulder

or a spike driven into a gravel road surface. These

objects are subject to movements of a few centimeters

to a decimeter or more in a year's time, but

they are adequate for the surveyor's needs. It

would be uneconomical to spend the time and

money necessary to set higher quality bench marks.

Another surveyor might be concerned with laying

out a major highway that could take years to

complete. Therefore, the control must be more

stable in its position and longer lasting. To this

surveyor, a stable point could be represented by a

concrete post extending to a depth of a meter or so,

or a spike in the side of a large utility pole. These

bench marks might hold their elevations within a

few centimeters while the project is being carried

out. It follows that the bench mark stability required

depends on the precision of the survey being

carried out and the duration of the project

for which the elevations are needed.

The National Geodetic Survey (NGS) of the National

Ocean Survey is responsible for establishing

and maintaining the National Networks of Geodetic

Control. The survey markers comprising

these networks serve as basic reference points for

numerous surveying, engineering, mapping, land

use planning, and scientific projects. If the networks

are to adequately serve these purposes, they

must be established to a high degree of accuracy

and monumented in a manner that best preserves

their original geodetic positions.

Stability requirements for the National Vertical

Network control points have increased significantly

in recent years due to continually advancing

technology. Both the ability to determine elevations

more precisely and the need to know elevations

more accurately have resulted from this

technological boom. Uses have increased from

basic control for boundary surveys and mapping

to large scale planning and construction of transportation

systems such as interstate highways and

transcontinental pipelines. More recently, increased

emphasis on crustal motion studies and

control for missiles, satellites, and spacecraft has

brought about a need for more accurately known

positions and, consequently, more stable control

points.

1

Elevations are referenced to a level surface, or

geoid, which is approximately equivalent to mean sea level.1 Not even the Earth's crust, which averages

35 kilometers in thickness, is stable relative to

the geoid. Young mountains are uplifting while

areas of the ocean floor subside. Ideally, a bench

mark used strictly for control should remain

motionless with respect to the geoid. Since the geoid

is intangible, the only basis we have for appraising

bench mark stability is the Earth's crust,

even though it is in constant motion. A monument

can be considered as stable as possible if it is motionless

with respect to the crust.

To clarify this, a distinction must be made between

crustal motion and motion within the crust.

Crustal motion is movement of the crust as a

whole. It is caused by phenomena such as isostasy

(the concept of the crust floating on the mantle)

and tectonic plate movement. Motion within the

crust originates above the base of the crust.

It is motion originating above the base of the

crust that we would usually like to prevent from

being transmitted to our bench marks. Prevention

being impossible, the next best thing is to reduce

the motion's effects. This can be done by (1) minimizing

surface effects and (2) with the aid of geological

information, avoiding or accounting for

movements of deeper origins.

The following chapters deal with identification

of the various factors that can cause changes in

bench mark elevations, and steps that must be

taken to set high-quality bench marks. These

marks include disks set in bedrock or structures,

sleeved rod type bench marks, rod marks with

disks, and some miscellaneous types.

2. SOURCES OF VERTICAL INSTABILITY

The subject of bench mark instability can be

more easily understood if it is separated into two

categories characterized by the depths at which

movement originates. Those with their roots within

about 15 meters of the surface will be called

"near-surface sources of instability," while those

that originate below about 15 meters will be called

"subsurface sources of instability." If the effects of

near-surface sources of instability cannot be avoided

by prudent selection of the bench mark

site, they can be counteracted so that they are not

reflected in the bench mark elevation. Subsurface

effects usually cannot be economically counteracted

by a suitable bench mark design so they must

be avoided or accounted for.

Bench mark movement can be likened to that of

a float bobbing up and down on the surface of the

ocean. The total vertical movement of the float is

the result of accumulated movements caused by

sea (locally generated choppy waves), swell (long,

rolling waves from a distant origin), and tide. At

times, these individual effects act together, amplifying

the total movement. For example, the

float might be lifted by a sea which is on the crest

of a swell at high tide. Other times, one effect will

tend to cancel another, as when the float is on the

crest of a wave which is in the trough of a swell.

At any rate, the float is in motion with respect to al

reference surface, which in this case is the ocean

floor.

To correlate this to bench mark movements, the

respective counterparts of sea, swell, tide, and the

ocean floor are near-surface movements, movements

within the crust, motion of the entire crust,

and the geoid.2 It would be ideal if we could fix the

bench mark to the geoid as we can anchor a piling

to the ocean floor to eliminate tidal motion. However,

there is no analogous way to counteract the

effect of crustal motion on a bench mark.

In the ocean, the effect of swell could be avoided

in some areas by making use of an existing breakwater,

harbor, or bay. Similarly, with proper

bench mark site selection, many movements within

the crust can be avoided, but choice of a location

is not as obvious. Considerable geological information

is needed to determine which areas exhibit no

subsurface instability.

Finally, the effects of sea in many situations can

be avoided. Where this is not possible, they can be

economically counteracted by building a small

floating barrier. Essentially, this is what can be

done for vertical control points. The sleeved class

A rod mark (see fig. 4, page 16) consists of a steel

rod that is isolated from near-surface motion by

the sleeve.

Origins in the Subsurface

Crustal Motion

First among the subsurface causes of vertical

movement is crustal motion. Even if it were possible

to prevent this movement, it would be undesirable

in many cases. Crustal motion studies are

an important application of leveling data. The

movement of one area of the crust in relation to

another serves as the basis for these studies. To

determine this, knowledge of crustal motion with

respect to the geoid is not essential. What is necessary

is to know which bench marks reflect only

crustal motion. Referring to the parallel drawn

with the sea surface, if a float is to be used to monitor

tides, it must be known that the effects of seas

and swell have been eliminated.

1 A concise, easily understood description of the geoid is given in appendix B.

2 The gravitational effects of the sun and moon exert an

influence on land masses just as they do on the oceans, causing a phenomenon known as "Earth tides." No analogy

for Earth tides is made in this parallel.

|

2

Caverns and Mines

Caverns and underground excavations contribute

to vertical movements on the surface of the

Earth. Sometimes the motion is abrupt as is the

case with sink holes, and other times their effects

result only in gradual subsidence. When crustal uplift

is occurring simultaneously with subsidence

caused by a gradual caving in of an underground

mine, the wrong conclusion can be drawn about

the stability of an area. In general, the National

Geodetic Survey is not concerned with monitoring

subsidence caused by underground excavations

and caverns. Since it is too costly to anchor bench

marks below the depth of disturbance and isolate

monuments against such movement, these areas

must be avoided wherever possible.

Pumping

Subsidence is also caused by pumping of oil or

water. When fluid is removed from the ground,

the resulting decrease in pressure allows gravity

to pull down the overlying soils. Associated with

this is piping, or the removal of fines from a soil

stratum, which aggravates the situation. Again, in

carrying out its basic mission of developing and

maintaining a network of geodetic control, NGS is

not primarily concerned with monitoring this

type of motion. Except where subsidence is the subject

of special study, such as in the Houston, Tex.,

area and Santa Clara Valley, Calif., these areas too

should be avoided wherever possible.

On or Near-Surface Origins

Impact

The reliability of a bench mark elevation is

largely dependent upon its exposure to impact.

The results of impact can range from an infinitesimal

change in elevation as a result of being stepped

on to total destruction caused by earth-moving

equipment, which is perhaps the most common

cause of bench mark loss. NGS bench marks have

been designed to minimize the chances of vandalism,

tampering by souvenir hunters, and impact

which is relatively small in magnitude.

For class A rod marks, this is accomplished by

three precautionary measures: first, the datum

point is set slightly below ground level; second, a

protective pipe is placed around the datum point;

and third, the bench mark component which is

imprinted with the NGS logo, and might be considered

a worthy souvenir, is not an integral part

of the datum point.

By their inherent nature, other types of NGS

bench marks are not vulnerable to relatively

slight impact. Heavy impact, such as that caused

by construction equipment, cannot be counteracted

by economical design so it must be avoided

by judicious placement.

Frost Heave

Besides disturbances caused by human intervention,

there are a great many resulting from

natural phenomena. Of these, frost heave is one

of the most severe. The occurrence of frost action

depends on three factors: freezing temperatures;

available water; and certain soil characteristics,

most notably soil particle size. The absence of any

one of the essential conditions precludes the occurrence

of frost heave.

For example, it is the influx of additional water

into a soil's freezing zone after the freezing has

already begun that results in excessive frost heave.

The freezing of water initially present does not

cause a significant problem. When the water table

is near the surface, additional water is available to

be drawn up into the freezing zone causing the

frost heave problem. A water table within 2 meters

of the ground surface indicates a potential hazard

and it is normally further from the surface on hills

than in low-lying areas. Consequently, less severe

frost heave can be expected to be found on hills.

Even though water is available, significant frost

heave will not occur unless the soil can draw it up

and hold it in the freezing zone. Soils which are

capable of this are called "frost susceptible." The

main factor in determining frost susceptibility of

a soil is particle size distribution. Coarse-grained

soils contain spaces that are too large to draw up

and hold water. At the other extremity, many clays

are impervious to water. (Clays, however, are detrimental

for reasons other than frost heave as

explained in other sections of the manual.) The

soils most susceptible to frost action, and therefore

to be avoided where freezing occurs, are silts and

silty sands with soil particle sizes less than 0.02

millimeter (U.S. Army Corps of Engineers 1967).

Shrinking and Swelling of Soil and Rock

Another phenomenon that can cause bench

mark instability is shrinking and swelling of soil

due to changes in moisture content. The magnitude

of soil volume change depends upon two

factors. One is the character of the soil, including

particle size and distribution, degree of cementation,

and, most importantly, mineralogy (Patrick

and Snethen 1976). Fine-grained soils containing

certain clay minerals, particularly montmorillonite,3

are highly expansive.

3 Montmorillonite is a clay-mineral made up of layered,

plate-like particles separated by water. The addition of more

water causes the particles to separate even more until they

finally disperse.

|

3

The other factor governing the shrinking or

swelling of a soil is the measure of its variation in

moisture content. Seasonal climate variability

provides a good indication of the degree and depth to which volume change will occur.4 An expansive soil subject to either a consistently moist or dry climate year around will not exhibit a change in volume,

but if the climate is wet during one season and

dry during another, a volume change will occur. Figure 12 (page 33) separates the United States into areas of differing climate variability. The higher the value of the climate factor, the

more variable the moisture content of the soil.

This expansive character is not limited to soils.

Sedimentary rocks are those which were formed by the consolidation of sediments. If the parent materials were of an expansive nature, the rock itself will likely have this characteristic to a surprisingly high degree. Substantial pavement damage has occurred on some highways founded on sedimentary bedrock when the water content has been altered.

Soil Expansion and Contraction

The terms "expansion" and "contraction" indicate changes in volume resulting from a change in temperature rather than a change in moisture content.

Like other materials, soil expands when its temperature rises and contracts when its temperature

is lowered. It differs from most other materials in that the range of temperature variation is not constant throughout its depth. At the surface, the temperature variation is near that of the air.

At some depth, the temperature is nearly constant

throughout the year. In unfrozen soils, expansion and

contraction due to temperature change is negligible,

but in frozen soils they are factors to

consider. In permafrost, temperature change can

have a significant effect on a bench mark down to

a depth of about 10 meters (Bozozuk et al. 1962).

Slope Instability

Slope instability covers a wide range of movements ranging from rockslides and mudflows to the nearly imperceptible movement known as creep. Rockslides and mudflows are obvious and would probably result in the total destruction of a bench mark. Creep presents a greater problem to monumentation because it could result in only a slight change in the bench mark elevation which could lead to erroneous conclusions. Evidence of creep can sometimes be witnessed in leaning utility poles where the upper layer of soil slides in relation to that beneath it.

Gravity is the main force that produces creep, but gravity can be aided by a number of other factors, among which the presence of moisture is probably the most dominant. In some instances, a small amount of water can increase cohesion and retard the flow of soil downhill. More often, water

decreases friction between soil particles, allowing

them to flow more rapidly. When moisture is confined to the upper layers of a slope by an impermeable substratum, the likelihood for creep is quite

high.

Sometimes a slope can be stable until a cut is

taken from it which upsets the equilibrium and starts a slide. If the cut was taken from an area

providing substantial support to a slope, the slide will occur rapidly. When the slope is less steep or

provides more of its own support through cohesion

of the soil, a cut will have no effect or result only

in creep. Highways are notorious for producing

slides in some parts of the country.

Soil Consolidation

When a soil mass is subject to loading, the soil particle orientation undergoes a change resulting in a condition of closer packing and smaller voids. The longer the load remains, the more stable the

particle reorientation becomes, until a condition

of equilibrium is finally reached. If a load is removed, rebound occurs.

Many kinds of loads can cause a soil mass to consolidate significantly. Large structures can cause soil consolidation resulting in settlement of the

structure. They are often constructed in such a

manner that they do not exceed a specified settlement, or at least a certain settlement rate. The total allowable settlement is usually a few centimeters. The rate occurs rapidly at first and decreases with time. Some structures continue settling for many years after construction has been completed. Besides compressing the soil directly beneath it, a new building causes the surrounding soil to be drawn down.

Water reservoirs exert tremendous stresses on soil deposits. As a reservoir is filled or drained, the soil mass below it compresses and rebounds accordingly. As with structures, the surrounding soil is also affected by the loading and unloading. Large rivers also exhibit this trait to some extent with the seasonal change in water level.

A special case of consolidation due to loading can be seen in manmade deposits or fill. Not only do these deposits exert a pressure onto what may be a compressible soil below, but they themselves are subject to consolidation. When the purpose of fill is other than to improve the subgrade of a construction site, it is usually deposited loosely, and will compact under its own weight. Fills are usually deposited in small or narrow areas. Examples include levees, landscape improvements, and disposal sites for undesirable materials such as trash, overburden, and dredge deposits. However, sometimes the areas can be very extensive, as in the case of reclaimed strip mines.

4. Soil mechanics being a complex science, the maximum

depth at which soil is affected by this phenomenon is not

universally agreed upon. Here, it is assumed to be 15 meters.

|

4

Erosion

Impairment of some bench marks can be attributed

to erosion. Soils in or on which a monument

is set are subject to removal by the action of

wind and water. This can result in the monument

being obviously displaced, or only a subtle disturbance

rendering it unsuspectingly unfit for use

as a geodetic control point. Undercutting can occur

along the outsides of curves in rivers and embankments

near large bodies of water where

storms are likely to occur. It is conceivable that

wind erosion could also present a problem in some

locations, but it would probably result in the loss

by burying a bench mark rather than changing its

elevation.

Motion Intrinsic to the Monument

Choice of materials for a bench mark monument

is critical for two important reasons. First,

ultimate deterioration of materials results in the

loss of a bench mark's reliability. The outmoded

copper clad rod mark (page 44) has been known to

corrode to such an extent that sections of the rod

have separated entirely. Failure of a bench mark

from this cause would not be abrupt. In fact, it

could be difficult to detect. For this reason, when a

monument is recovered for releveling, it should be

tested to ascertain its condition. For rod type bench

marks this can be accomplished by grasping the

rod and pulling it to make sure its integrity has

been retained.

Secondly, a bench mark's elevation can change

with the expansion and contraction of the monument

due to temperature change. Theoretically,

this can amount to changes on the order of a millimeter

or more between hot and cold seasons. In

choosing bench mark materials, the thermal coefficient

of linear expansion must be considered.

If modifications involving changes in materials

are made to the prescribed designs for rod marks,

materials having a direct bearing on the bench

mark elevation should be limited to those having

a coefficient less than 20 X 10-6 cm/cm per oC.

Intended Stability of NGS Bench Marks

From the information in this chapter, it is evident that the causes of instability vary widely in both

depth of origin and geographical extent. To

counteract deep subsurface activity would be economically

unfeasible, so bench mark specifications

for the National Vertical Control Network have

been developed to resist movements at or near the

surface. Among such movements are those caused

by impact, frost heave, shrinking and swelling of

soils, soil expansion and contraction, and in some

cases where the effect is not too deep, consolidation.

Except for consolidation, bench marks set as

described herein can always be expected to resist

movements from these causes.

To accomplish this objective, most bench marks

must be anchored below the depths at which these

movements originate. Mere massiveness does not

insure stability. This point is extremely important

to bear in mind. Even a very large building is subject

to vertical displacements beyond those tolerable

if it rests on a shallow foundation in expansive

clay.

3. CONSIDERATIONS IN SELECTING A SITE

The most effective precaution that can be taken

to assure a bench mark's stability and survival is

to choose a good location for setting it. Because

there is such a wide variety of situations that can

be encountered when setting the monuments, it is

impossible to cover them all in a manual. The ultimate

selection of a site is necessarily left to the

discretion of the mark setter and it is imperative

that good judgment be exercised. There are many

things to consider. Table 1 (page 11) will help keep

them in perspective.

Security

Foremost on the list of considerations is the

bench mark's susceptibility to damage or destruction,

which is probably the major cause of bench

mark disturbance. In view of the great expense of

leveling, foresight spent to preserve a monument

is well worthwhile. Anticipate construction that

might occur at the location. Is the site in the path

of a future highway, waterway, ditch, or pipeline?

Will an adjacent shopping center or parking lot be

expanded in the foreseeable future? Is the prospective

bench mark site near a potentially active

mine or quarry? Highway maintenance often involves

the widening of its surface and the straightening

of curves. Setting the marks near the edge of

the right-of-way and on the outsides of curves increases

their chances for survival.

Conversely, the outside of a bend in a river

should be avoided because erosion eventually

undercuts the bank. Undercutting can also occur

on shoreline scarps where stormy waters slowly

but surely wear away the embankment. Do not set

bench marks at these locations. Flood plains

should be avoided when otherwise comparable

sites can be used because marks may be buried in

sediment or washed out.

Often, sites can be located which provide natural

protection for the monuments. Locations near the

edge of the right-of-way, well away from a highway

surface, provides protection from mowers and

other maintenance vehicles. Property fence lines

and utility poles usually remain in place for years

and afford good protection for marks. Structures

which are of themselves not suitable for bench mark settings prevent vehicles and equipment

from damaging monuments that are set adjacent

to them. And finally, private property and public

areas such as parks and cemeteries provide excellent

sites from a standpoint of survival.

5

Utility

Availability to users is another important consideration in choosing a bench mark site. The major use of NGS bench marks is to provide vertical control for other surveys. If the bench mark

cannot be found or conveniently leveled to, its

worth is questionable. Many users first inadvertently find a survey mark, then request information about it. Others use vertical descriptive information to locate control points near a proposed engineering project; so locate bench marks where they can be accurately described.

Again, foresight must be used when selecting the exact location. A bench mark set flush with the ground is easily concealed with debris. Are there nearby objects that can be used to reference the monument? Are these objects fairly permanent? Will the measurements define a precise point where the hidden bench mark can be found?

To enable the mark setter to situate a monument where its position can be accurately described, a familiarity with referencing techniques is required. Bench marks are usually located in

the following manner: First, directions are given

to the general area in which the bench mark is

located. Normally, this puts the individual within

100 meters or so of the monument. Then the bench

mark is found by following distances and directions

from prominent reference objects. These distances

and directions establish lines-of-position

(LOPs). The prominent objects are referred to here

as "origins."

For example, a bench mark can be referenced by

stating a distance and direction from the corner

of a house as follows: "The monument is 35.8

meters northeast of the east corner of the house."

(See fig. 1a.) In this case, there is one origin and

two LOPs. The origin is the east corner of the

house. One LOP is referred to as "35.8 meters

[from]. . . the east corner of the house." It defines

a circle with a radius of 35.8 meters and its center

at the east corner of the house. The other LOP is

given as "northeast of the east corner of the

house." It defines a line beginning at the east

corner of the house running at an azimuth of 45°

east of north.

At least two LOPs are required to define a point.

If the description read only "35.8 meters from the

east corner of the house," the bench mark could

be anywhere on the circle with a radius of 35.8

meters and a center at the east corner of the house. Or, if the description read only "northeast of the

east corner of the house," the mark could be anywhere

on the line beginning at the east corner of

the house and running at an azimuth of 45° east of

north. In either case, it would be difficult to find.

Sometimes more than two LOPs are required to

define a point. "The bench mark is located 26.7

meters south of the centerline of the highway and 10.2 meters from a 40-centimeter oak tree." Two LOPs are given by this statement, but they define more than one point as can be seen in figure 1b. An additional LOP, such as a direction from the water tank or tree, is required for the unique point to be located.

The important concept to be concluded is that the more nearly perpendicular the angle at which lines-of-position intersect, the more accurately a position can be determined and the easier it will be to locate. (See figs. 2a and 2b.) To apply this concept to bench mark setting, consideration should be given to the ease with which future recovery can be made from the reference measurements. Other considerations in bench mark placement rarely restrict the site to such a limited area that this cannot be done. Leeway of just a few meters is usually enough to make the difference between a mark that can be accurately referenced and one that cannot.

Stability

Advantageous Topographic Features

Crests of hills are good places to set bench marks

for three reasons. First, the problem of slope instability

is eliminated. Even though the neighboring

hillside might be sliding, the summit will remain stable. Second, frost heave is less likely with

the increased separation from the water table. And

third, the consistency of the soil will tend to be

more firm.

Effect of Soil Grain Size

Whenever soil types can be ascertained, it is

preferable to choose a site with coarse-grained

soils over one with fine-grained soils. Most of the

problems associated with soil movements are attributable

to the fine particles it contains. The

fraction of grain sizes less than 0.02 millimeter

governs whether or not a soil is frost susceptible.

Soils susceptible to high volume change due to

variation in moisture content are normally clays,

which are fine-grained. Also, poorly drained clays

provide environments conducive to corrosion.

Avoid sites with fine-grained soils whenever an

alternative is available.

One way to determine the type of soil in the locality is to examine that which has been exposed by

digging, especially where a bank has been left exposed. Look at soil grain size in nearby highway

cuts and excavations. Good drainage is usually inherent

in coarse-grained soils and therefore can

also be used as an indication. It can be recognized

by uniform coloration with depth.

6

(a) Bench mark referenced to house corner.

(b) Bench mark referenced to tree and road centerline.

Figure 1. - Referencing of bench marks.

7

(a) LOPs cross at right angles.

(b) LOPs cross at shallow angle.

Figure 2. - Intersection of lines-of-position. Light shade indicates range of measurement errors. Dark shade indicates area in which monument could be found.

8

Effects of Vegetation

The presence of vegetation, particularly trees,

has marked influence on the stability of the upper

layers of a soil mass. Trees, underbrush, grass, and

moss act as insulation, reducing the depth of the

active frost zone and thus reducing frost heave.

However, the problem of expansive soils is aggravated

by vegetation. In seasons of abundant

rainfall, vegetation exerts very little influence on

soil volume change. When the weather is dry and

only a little free water is available in the soil, trees

and other plants draw even more out than normally

is lost through evaporation and lowering of

the water table. This results in even greater shrinkage.

With trees, this effect occurs within a distance

from the trees roughly equal to their heights

(Bozozuk and Burn 1960).

Areas covered with thick vegetation should be

avoided even where expansive soils do not exist

because vegetation will conceal a bench mark,

making it of much less value than one that is open

to view. Do not place bench marks near lone trees

because this will subject them to disturbances

from growing roots.

Geological Considerations

It will not be feasible to determine the nature

and extent of subsurface geological activity in

many instances. Nevertheless, it is an important

consideration that should never be overlooked

when the means are available. A generally stable

area may have pockets of unstable ground within

it, and detailed geological data are required to determine

this. Caverns and underground mines,

and water and oil bearing strata subject to pumping

are especially prone to cause significant subsidence.

Bench marks established strictly for geodetic

control should not be set in these areas.

Geological information is available through

Federal, State, and even private organizations.

General overviews of karsts (subterranean cavities),

slope instability, and the like are available

from the U.S. Geological Survey. For more specific

information on larger scale maps, the individual

State Geological Surveys, State Departments of

Natural Resources, universities, and public

utilities commissions must be contacted. These

agencies can provide pertinent geological data

including maps of underground mines, cavernous

areas, slope movements, and areas subject to subsidence

from the pumping of oil, gas, or water. Liaison

with these organizations is a necessity.

Whenever possible, sound bedrock should be

used for a bench mark setting. However, it is often

difficult to determine whether or not an outcrop

is indeed sound bedrock, the decision being

based mainly on visual evidence of only the exposed

portion of the formation. Where a large portion

of the outcrop is exposed, try to ensure that

the part in which the disk will be set is essentially

intact with the rest of the outcrop. Large outcrops

with widely spaced fractures and crevices can be

considered bedrock for mark setting purposes.

Where only a small portion of the outcrop is visible,

use a pry bar to make certain the intended

setting is not a separate boulder.

Examine the surface of the bedrock. Make sure

it is solid, and not in a state of deterioration. The

margin of weathered rock can be surprisingly

thick. If its surface has begun to crumble or has

deep fissures in close proximity, the outcrop is unsound

and should not be used. Another type of

bench mark will be more stable.

Some sedimentary rock contains detrimental

clay minerals, such as montmorillonite, but it is

difficult to determine this. When geological maps

or expert advice indicates that sedimentary outcrops

are expansive, they shall not be used for bench

mark settings. A site must be located in a structure

or another rock outcrop, or a rod type mark must

be used. Expansive bedrock will not be a problem

is if lies beneath sufficient overburden because it

will not be subject to variations in moisture

content.

Structural considerations

Structures are subject to movements from any

of the sources pointed out in chapter 2. Fixing a

bench mark disk on a structure by no means assures

that it will be a good geodetic control point.

Before setting the disk, determine whether or not

the structure will be at least as stable as a class A

rod mark (page 14). If not, use the class A or B rod

mark instead.

Relating the stability of a large structure to that

of a class A rod mark can be accomplished by (1)

comparing the depth of the structure's foundation

to the required depth for the sleeve (table 2, page

27), and (2) assuring that the structure is a multi-story

concrete, masonry, or steel unit. The class A

rod mark sleeve is set to a depth below that affected

by expansive soils and frost heave. For comparable

stability, a massive structure's foundation need

not be as deep as the sleeve because the weight of

the structure can resist some of the force exerted

by the ground which tends to move it. Also, the

structure itself will have a shielding effect on the

soil below, making conditions such as temperature

and moisture content less variable. If its

foundation is at least a quarter as deep as a class A rod mark's specified sleeve depth, a massive structure

will be considered stable. Small structures, such

as semaphores, concrete culverts, platforms, retaining

walls, bridges, etc., must never be used. Very large bridges can be used only if it is positively determined that the structural member in which the disk will be placed rests directly on bedrock.

9

Since most structures are expected to settle both during and some time after construction, those less than 5 years old must not be used as settings for bench marks unless the foundations are on bedrock. Choose a structure that has a long life expectancy. Modern buildings will probably remain undisturbed a long time, but make sure that they have not been too newly constructed. Older buildings may last a long time if they have historical signficance.

Caution must be taken to assure that the disk is placed in a spot that is an integral part oft he structure

s foundation or fixed rigidly to it. Placing a disk on an appendage, such as steps entering a building,

is unacceptable unless the appendage has its own foundation of sufficient depth. Avoid places

which might be damaged or covered during, construction of an addition to the structure. Building entrances are especially susceptible to reconstruction.

Miscellaneous Areas To Avoid

As explained in the chapter on sources of instability, sites near water reservoirs and large rivers, where the water level is variable, can rise and fall due to rebound and compression of the soil. This movement might be thought by the layman

to be minor, but in terms of precise geodetic measurements, it is not. Where possible, bench marks

should be established a few hundred meters from the confines of these sources of ground activity.

Permafrost has a stabilizing effect on bench marks anchored to a sufficient depth within it, but significant expansion and contraction of frozen ground due to temperature variation can occur to a depth of about 10 meters. A bench mark anchored below this depth can be expected to be quite stable. In regions where permafrost normally exists near the surface, thawing influences can keep the ground in an unfrozen condition to a depth greater than that which is prevalent. Any body of water, such as a pond, lake, or river, will have this effect. Other influential effects include buildings, roads, pipelines, and, in short, any mark of civilization.

Corrosive Environment

The rate at which a material will corrode or

deteriorate is affected by its environment. Two conditions are required before corrosion can occur. (1) The metal being corroded must be in contact with an electrolyte, or liquid capable of conducting electric current. This makes it possible for certain chemical reactions to occur. Electrolytes vary widely, ranging from a minute amount of nearly pure water formed by condensation, to sea water. (2) There must be a dissimilarity in two areas of the surface being corroded. This could result from the presence of strains or inclusions in an alloy, the contact of dissimilar metals, or a multitude of possibilities between these extremes.

Environmental factors governing the corrosive character of a soil are principally the degree of aeration and the presence of water-soluble salts. Aeration is important because many metals need oxygen to form a dense, tough layer of metallic oxide on their surfaces, which prevents further

corrosion by isolating the remaining metal from the electrolyte. Aluminum and steel protect themselves in this manner. In addition, when one area of a metal is in an environment with a good supply of oxygen while another area lacks oxygen a

condition of dissimilarity is set up in which corrosion is accelerated. An example of this can be seen in a partially submerged piece of iron. That portion above water is supplied with more oxygen than the portion below water. At the waterline these dissimilarities are close to one another, resulting in intensified corrosion.

Water-soluble salts have an effect on corrosion In two ways. First, the ions that form when salts dissolve improve the capability of the electrolyte to carry current. The greater the ability of the electrolyte to carry current, the faster corrosion will occur. In both atmospheric and underground corrosion, water is normally the electrolytic medium.

Water with dissolved salts is a better electrolyte than pure water. The salts most often found in highly corrosive soils are sodium chloride (NaCl), commonly known as table salt, sodium sulfate (Na2SO4), calcium chloride (CaCl2), magnesium chloride (MgCl2), potassium sulfate (K2SO4), and calcium bicarbonate (Ca(HCO3)2) (Romanoff 1957).

The second effect of water-soluble salts is the influence they have on the formation of the dense, tough protective layer which forms on the surface of certain metals. Sometimes this layer cannot form in the presence of various ions. For example, aluminum is normally quite noncorrosive because aluminum oxide quickly forms on its surface. However, in the presence of dissolved salts, the oxide layer does not form densely enough to prevent

infiltration of the electrolyte, so corrosion

continues at a high rate.

10

| Table 1.-Summary of measures taken to set high-quality bench marks |

COUNTERMEASURES

(Discussed on page no. shown in parentheses)  |

|

|

|

|

|

|

|

|

|

|

|

|

| Use disk set in bedrock (13) |

X |

X |

X |

X |

X |

X |

X |

|

|

|

|

X |

| Seek coarse-grained soils (6) |

|

X |

X |

|

|

|

|

|

|

|

|

|

| Seek well-drained soils (9) |

|

X |

|

|

|

|

|

|

|

|

X |

|

| Seek well-aerated soils (10) |

|

|

|

|

|

|

|

|

|

|

X |

|

| Set on crests of hills (6) |

|

X |

|

|

X |

|

|

|

|

|

|

|

| Seek soils with high resistivity (12) |

|

|

|

|

|

|

|

|

|

|

X |

|

| Natural/readymade protection a (5) |

X |

|

|

|

|

|

|

|

|

|

|

|

| Anticipate future construction b (5) |

X |

|

|

|

|

|

|

|

|

|

|

|

| Set near edge of right-of-way (5, 12) |

X |

|

|

|

|

|

|

|

|

|

X |

|

| Bench mark design (3, 12, 14) |

X |

X |

X |

X |

|

|

|

|

|

|

X |

|

| Anchor sleeved rod below level of disturbance (14) |

|

X |

X |

X |

|

|

|

|

|

|

|

|

| Set disk in massive, deep structure (9) |

|

X |

X |

X |

X |

|

|

|

|

|

|

|

| Historically significant structure (10) |

X |

|

|

|

|

|

|

|

|

|

|

|

| Modern buildings (10) |

X |

|

|

|

|

|

|

|

|

|

|

|

| Remain distant from thawing effects c (10) |

|

|

|

|

|

|

|

X |

|

|

|

|

| Ensure good referencing (6) |

|

|

|

|

|

|

|

|

|

X |

|

|

| Avoid heavy vegetation (9) |

|

|

X |

|

|

|

|

|

|

X |

|

|

| Avoid river banks (5) |

|

|

|

|

|

|

|

|

|

|

|

X |

| Avoid flood plains (5) |

|

|

|

|

|

|

|

|

|

X |

|

X |

| Avoid shoreline scarps (5) |

|

|

|

|

|

|

|

|

|

|

|

X |

| Avoid salt water shorelines (12) |

|

|

|

|

|

|

|

|

|

|

X |

|

| Avoid areas as determined by geological data d (9) |

|

|

X |

|

X |

X |

X |

|

|

|

|

|

| Avoid expansive bedrock (9) |

|

|

X |

|

|

|

|

|

|

|

|

|

| Avoid new structures (less than 5 years old) (10) |

|

|

|

|

|

|

|

|

X |

|

|

|

a Includes fence lines, utility poles, structures, and private and public grounds.

b Includes highways, parking lots, buildings, pipelines, and waterways.

c Includes lakes, rivers, buildings, and pipelines.

d Overviews of karsts, slope instability, shale outcrops, oil and gas bearing formations, etc., from the U.S. Geological Survey, States' Geological Surveys, States' Departments of Natural Resources, and public utilities commissions. |

11

Of the types of monuments which may be used

in the National Vertical Control Network, only the class A and B rod marks (pages 14 and 25) are particularly

vulnerable to corrosion. The rods for

these marks will unavoidably be placed in corrosive

soils. As a protective measure, the rod is made

of type 316 stainless steel, which is more resistant

to corrosion in nearly all environments than other

affordable alloys. Even so, steps can be taken to

increase its life. It is most susceptible to corrosion

in poorly aerated environments and those in which

there are chlorides.

Iron compounds are commonly contained in

soils. Well-aerated soils are generally recognized

by their red, yellow, or brown colors resulting

from the oxidation of these compounds. Sites with

these soils should be sought for bench mark setting.

Poorly aerated soils are usually gray in color

due to the lack of sufficient oxygen to oxidize the

iron compounds. They may also be identified by

their poor drainage characteristics.

Avoid areas where there is a high concentration

of chlorides. When setting marks along highways,

keep them at least 10 meters from the road surface

where heavy salting might be done in winter;

setting along the edge of the right-of-way is generally

a good practice. Although it will sometimes

be impossible due to project requirements, try to

avoid salt water shore lines. When the purpose of a

project is to provide shore line control, stay off the

beach if project instructions will allow.

Finally, if the means are available to measure

soil resistivity, a good indication of the corrosive

character of a soil can be obtained. The more resistant

a soil, the poorer the electrolyte, and consequently,

the less corrosive it will be.

Safety

If a monument extends below ground level,

there is a chance of encountering underground

cables or pipes when installing it. This is especially

true when drilling a hole for the sleeved class A

rod mark (page 18), and the situation is more critical in

urban areas than in rural areas. Evidence of underground

utility lines often can be observed at the

surface. Waterlines are marked by valve boxes at

most street intersections. Avoiding the line between

valve boxes will decrease the chances of

hitting a pipe. Also, fire hydrants indicate where a

water main lies. Hydrants usually are placed within

a meter of the line and to the side away from the

street centerline. Most water and sewer lines lie

under the road surface, but some are placed adjacent

to it. Avoid the area between the street and

sidewalk.

Telephone and electrical cables are normally

laid from 1/2 to 1 meter below the surface. Housing

developments built in the 1960's and later are

much more apt to have underground cables than

those built before that time. The absence of telephone and power poles is conclusive evidence that

there are underground cables in the area, but the

presence of poles does not necessarily dictate

otherwise. Buried telephone lines usually run directly

between junction box pedestals or between

telephone poles. Electrical cables may be run adjacent

to telephone lines. Where an electric appliance

such as an air conditioning unit or flood

light is located apart from other structures, an

underground cable to it would probably run directly

from a metering device. Stay clear of that

path.

Gas lines are harder to detect. Meters and valves

are helpful if they are not too far apart. As with

telephone cable pedestals, do not drill on a direct

line between them.

If circumstances permit, the best way to avoid

problems is to contact the local metropolitan utilities

commissions. Underground pipe and cable

information can often be had by calling one centralized

office which maintains liaison with all the

various utility companies. When it is possible to do

reconnaissance a few days in advance of the actual

mark setting, this alternative will be efficient. If

this is not possible, it is advisable to use a pipe and

cable locator for detecting conductive materials

underground. However, these devices are not infallible.

Plastic, unreinforced concrete, and clay

tile pipe will not register on them. Get into the

habit of looking for "Buried Cable" signs. And

finally, set marks near utility poles, but not on line

between them when other considerations in site

selection will allow. Utility poles cannot be set over

water and sewage pipes.

4. INSTALLATION

Maintaining Good Public Relations

The purpose of the Federal Government is to

serve the public. Pertaining to the establishment

and maintenance of geodetic control, this principle

has at least two applications. One is to gain the understanding

and good will of the public. Another

is to project the credibility of the National Ocean

Survey/National Geodetic Survey through the

visible evidence of its mission-survey control

markers.

These objectives can be accomplished with only

a little extra effort. Always obtain permission from

the landowner when setting bench marks on private

property. Responsible officials must be consulted

when a prospective site is located on public

or corporate land. If approached in a polite and

tactful manner, a hesitant individual often can be

persuaded to permit installation at the desired site.

Most citizens can be convinced to take personal

interest in having a bench mark carrying NGS's

distinction on their property. Appeal to the individual's public spirit. Explain what bench marks

are used for, the need for their stability and durability,

and the expense involved with replacing

them. The setting of bench marks provides an excellent

opportunity to make the public aware of

NOS/NGS activities. Under no circumstances

shall a bench mark be installed on an unwilling

property owner's land, thereby provoking hostility

toward the Federal Government.

12

The importance of a clean, neat installation cannot

be overemphasized. Not only does it help

maintain friendly relations with the local citizens,

but it also upholds the esteem of the Federal

Government. Sloppy bench mark installations by

a few mark setters could understandably lead users

to believe that the whole leveling program is run

in a haphazard manner. Do not allow this to

happen.

Special Considerations at Line Intersections

Level line intersections are of prime importance

when it comes to mathematical adjustment of a

vertical control network or portion of it. Junction

points are used for the initial adjustment of the

system. Intermediate elevations are not taken

into account until after this initial phase of the adjustment.

As a result, no elevations can be better

than those at the junctions; therefore, only the

highest quality bench marks should be used there.

Sound bedrock should be used for these points

if at all possible. Relocating the point of intersection

as much as 10 kilometers to take advantage

of an outcrop would not be unreasonable. When

outcrops of sound bedrock are not available, choose

the next best location following the guidelines

enumerated in chapter 3. Other than bedrock

marks, only disks in structures and class A rod

marks as explained in succeeding sections are

permissible for first-order junction bench marks.

Once the location is found, steps must be taken

to preserve the junction by placing supplemental

monuments nearby which can also serve as junction

points. In the event the primary monument is

destroyed, the integrity of the network will remain.

At intersections of two first-order lines, a

minimum of three monuments shall be placed not

less than 0.5 kilometer apart. At intersections of

first- and second- or two second-order lines, a

minimum of two monuments shall be placed not

less than 0.5 kilometer apart. Junctions with third-order

lines need no special considerations. In all

cases, try to select sites that will not all be destroyed

by one common cause such as the widening

of a highway.

Disk Set in Bedrock or Structure

Sound bedrock is the most desirable setting for

a bench mark. Besides the ease with which a disk

can be installed in bedrock, it provides the most

stable setting that can be used in terms of both

underground activity and disturbances inflicted

by people. Always use bedrock when a suitable outcrop

exists. As a rule of thumb, the bedrock is good

if the distance between joints and fissures is greater

than 1 meter.

The National Geodetic Survey bench mark disk

(see fig. 3) is made of brass or bronze. It is about 9

centimeters in diameter and has a spherical surface

to support the foot of the leveling rod. Information

is imprinted on this surface to identify

the monument and to aid the user in obtaining

data on it. This logo is recessed so that it does not

interfere with placement of the leveling rod. A

deformed shank, about 7-1/2 centimeters long, is

silver-soldered to the bottom surface of the disk to

help prevent the disk from being dislodged. Disks

with tubular shanks can also be used.

The step-by-step procedure for setting the disk

in bedrock is as follows:

1. Stamp the designation and year on the top surface

using 4.75-millimeter (3/16-inch) steel

dies.

2. Pick a fairly level and accessible spot on the

outcrop that is intact with the bulk of the rock.

3. Drill a 2-1/2-centimeter hole about 10 centimeters

into the bedrock and recess the area

around the top of the hole to a diameter

slightly larger than that of the disk. When the

installation is completed, the top surface of the

disk should set level and flush with the surrounding

rock. Caution: Safety goggles should

be worn when drilling into bedrock or

masonry.

4. Remove the rock powder from the hole and

recessed area and fill the hole with clean water;

then pour cement into it. Mixing of the ingredients

is done right in the hole. By adding

more water and cement, make enough mortar

so that an extra amount is available to place on

the underside of the disk and, if applicable,

inside the shank. When the mortar is completely

mixed, it should be thick but still

workable.

5. Fill the depression on the underside of the disk

with mortar. For disks having tubular shanks,

also fill the shank with mortar. This is very important

because it will prevent the existence

of highly undesirable voids under the disk

once it is in place.

6. Place the shank of the disk into the drilled

hole and press the mark firmly into place.

Work the excess mortar around the outer edge

of the disk, making sure that it is smooth and

flush with the top surface. An exposed edge of

the disk would provide an area which could be

used by someone to dislodge it. Fresh mortar on the upper surface of the disk can easily be

cleaned off.

13

Figure 3.-NGS bench mark disk stamped with designation and year.

7. Sprinkle some dry cement on the exposed surface

of the disk; then rub it with a clean rag

using circular strokes. This will clean the disk

very nicely, removing all excess mortar from

its surface and recessed letters. Rubbing the

wet mortar around the edge of the disk in the

same manner will do no harm. On the contrary,

this is often done intentionally to finish

its surface and prevent cracking. Brush away

loose cement and make sure that the finished

product has a very neat appearance.

8. If there is a nearby crevice or spot of ground in

which a witness post can be conveniently set,

this should be done.

9. While the mortar is still wet, it must be covered

to prevent heavy rains from ruining its

surface and to conceal the disk from people

who might tamper with it. A piece of wood,

cardboard, heavy paper, or similar biodegradable

item will suffice.

10. The installation is not complete until all accumulated

trash has been picked up. Leave the

place in good order.

In setting a disk in a massive concrete or masonry

structure; first make sure the structure is

stable. Its foundation must extend to a depth that

equals or exceeds 25 percent of the specified depth

of the sleeve for the class A rod mark, as indicated

in table 2 (page 27). Furthermore, the foundation

must be at least as deep as the maximum depth of

frost penetration indicated on the map in figure 13

(page 34).

The disk can be mounted vertically in the wall

of a structure, but should always be set horizontally

if possible. The procedure for setting a disk

horizontally in a structure is identical to that for

setting one in bedrock. Make sure safety goggles

are worn when drilling into masonry or concrete.

Since for a vertical setting the hole for the disk's

shank must be drilled horizontally, the mortar

must be mixed separately. When drilling into

brick or other soft material, a hammer and star

drill should be used, rather than heavy power

equipment, to prevent extensive damage to the exterior.

The hole should be wetted before mortar is

put into it. After placing the shank of the disk into

the mortar filled hole, work it to the bottom edge

of the hole so that it will not settle askew while the

mortar is curing.

14

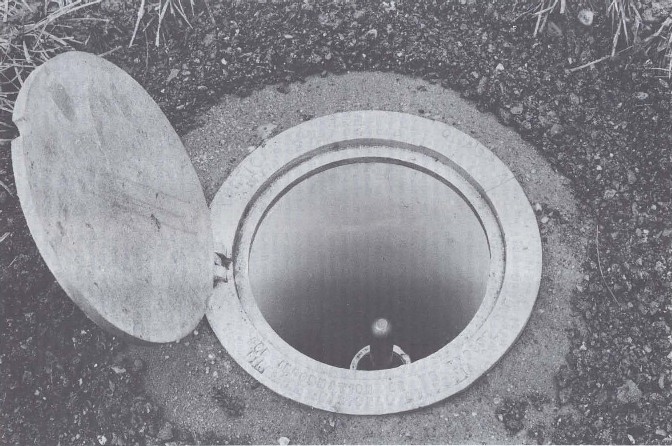

Class A Rod Mark

The class A rod mark is to be used whenever possible

where sound bedrock and substantially

stable structures are not available. The top of a

steel rod serves as the datum point. The rod itself

anchors the datum point to a stable stratum of

soil. In most areas a sleeve is required to isolate the

rod from soil movements occurring above the stable stratum.5 (See fig. 4.) This sleeve is omitted

where no soil movements are expected. At the surface

an encasement around the datum point provides

protection from impact and information to

the user. (See fig. 5.)

The rod is assembled from sections of 1.43-centimeter

(9/16-inch) type 316 stainless steel 6 coupled

with threaded studs of the same material. The

sleeve is made from 2.54-centimeter (1-inch)

schedule 40 polyvinyl chloride (PVC) pipe with

fittings to couple the sections. The annular space

between the rod and sleeve must be filled to prevent

water from infiltrating it. If water is allowed

to seep into this space, two problems will arise:

corrosion will occur; and when the water freezes,

stresses between the sleeve and soil will be transmitted

to the rod. The substance used as the filler

should be a grease or grease-like product with a

consistency that will remain soft at cold temperatures.

It must be insoluble in water, noncorrosive

to the rod and sleeve, and must have an extremely

long life expectancy.

The casement consists of a 12.7-centimeter (5-

inch) PVC pipe, 1/2-meter long, fitted with an

aluminum flange around its top edge. The flange

is imprinted with the standard information that

accompanies all bench mark monuments and is

stamped with the station's designation and year.

Its inside edge is recessed to accommodate a hinged

aluminum cover. This arrangement is placed around

the top of the rod, slightly below ground

level. Approximately 20 liters (2/3 cubic foot) of

concrete is then poured around it to hold it firmly

in place and to aid in recovery of the monument if

it becomes buried.

This type of monument has been designed to

prevent near-surface soil movements from changing

the bench mark elevation. The two major

kinds of movements it can counteract are frost

heave, and shrinking and swelling of expansive

soils. Averting these movements is accomplished

by extending the sleeve to the maximum depth to

which these soil movements are expected to occur.

Then the rod assembly, after being placed inside

the sleeve, is driven or pressed into the soil so that

it is anchored below the sleeve, and consequently,

below the layer of disturbance.

When frost heave can occur, the sleeve is placed

to a depth three times as great as the maximum

frost penetration indicated in figure 13 (page 34).

When any type of upright, such as a post, pile, or

pipe, is subject to frost action, the upward motion

caused by frost heave is normally greater than the

subsequent settlement after the ground has thawed.

Unless there is an opposing force, the object will

eventually be ejected from the ground. A sleeve

placed to three times the depth of frost will have,

in nearly all instances, enough friction between it

and the soil below the frozen layer to resist the

upward force of frost heave. In any case, the jacking effect of frost action will be retarded.

Consolidation of a soil mass can be counteracted

with this bench mark when it is placed to a sufficient

depth. As long as the sleeve isolates the rod

from the soil where consolidation (or rebound) can

have an effect, movement from this cause will not

change the bench mark's elevation. To be used

effectively in this manner, a geologist or soils expert

must determine where these movements

occur.

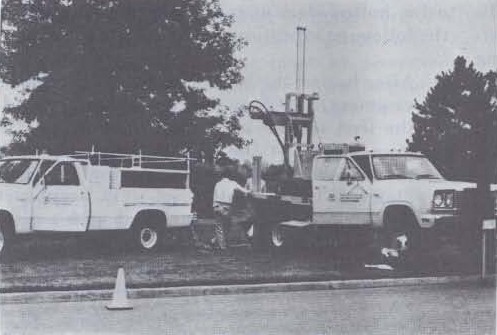

It is suggested that one of two methods be used

to place the 2.54-centimeter (1-inch) PVC sleeve,

though other methods might also prove effective.

(1) Where the soil is self-supporting, the cleanest

and quickest method is to use a small diameter,

conventional flight auger. Briefly, a hole is drilled

to the specified depth of the sleeve, the string of

augers used in drilling the hole is retracted, and

the sleeve is lowered into the hole. (2) Where the

soil is subject to caving, as in a loose dry sand, or

in working below the water table, a hollow-stem

auger can be used. The auger is drilled to the

specified depth, the bench mark sleeve is lowered

into place through the auger, and the auger is

retracted, leaving the sleeve in place.

When it is unknown whether or not a hole will

support itself, use the conventional flight auger.

If the hole caves before the bench mark sleeve can

be lowered into it, start over using a hollow stem

auger. Once some experience is gained in a particular

region, the mark setter will intuitively

know whether a conventional auger will likely

suffice or if efficiency would be lost in this trial-and-error method.

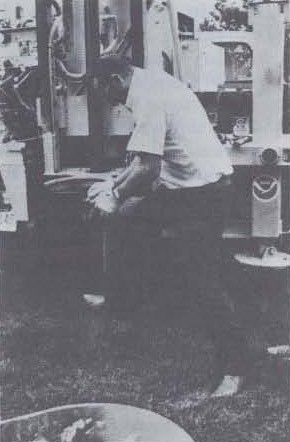

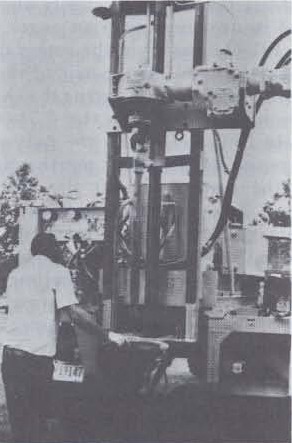

A suggested routine using the conventional

flight auger is given next. Some of the steps need

not necessarily be taken in the prescribed order.

Experience will dictate the most efficient manner

for a particular crew. One crew's method is pictorially

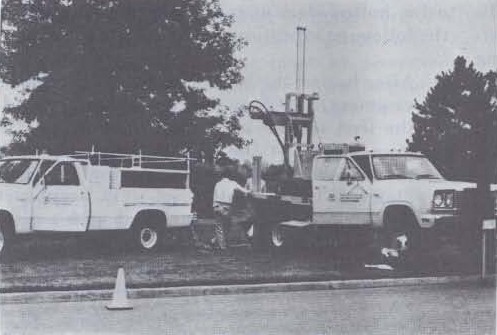

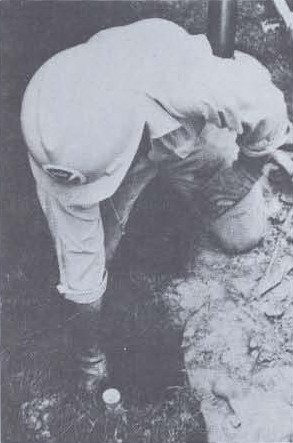

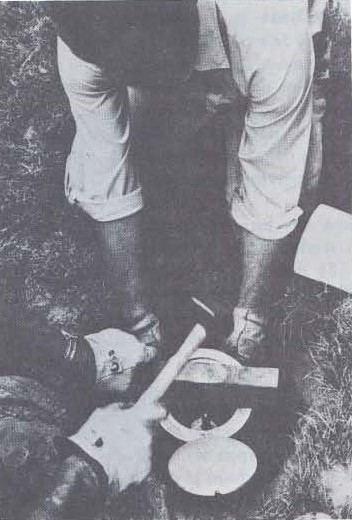

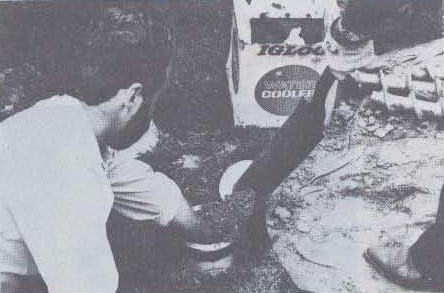

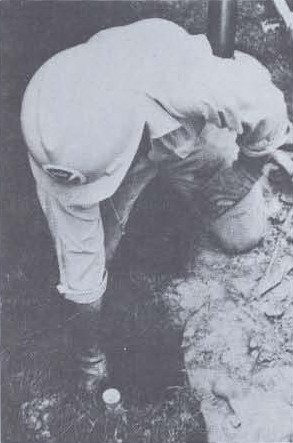

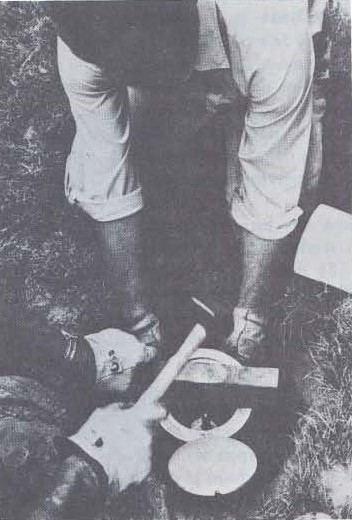

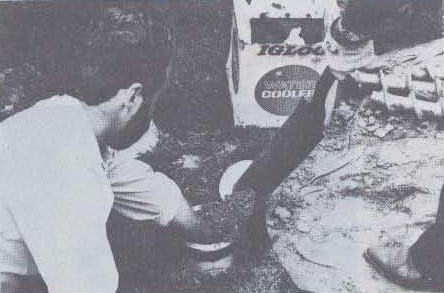

illustrated in figure 6 (pages 20-24).

| WARNING: Precautions must be taken before

drilling into the ground. Underground pipes

and cables can be damaged and can also cause

damage. to drilling equipment. Conceivably,

injury or death could result from drilling into

an electrical cable or gas line. (See "Safety,"

page 12.) |

5 Although it is somewhat detrimental from a corrosion

standpoint, the sleeve is normally essential for stability.

6 This alloy has the optimum combination of iron, nickel,

and chromium to combat corrosion in both weight loss and

pit depth, and yet remains economical.

|

15

Figure 4.-Sleeved class A rod mark.

16

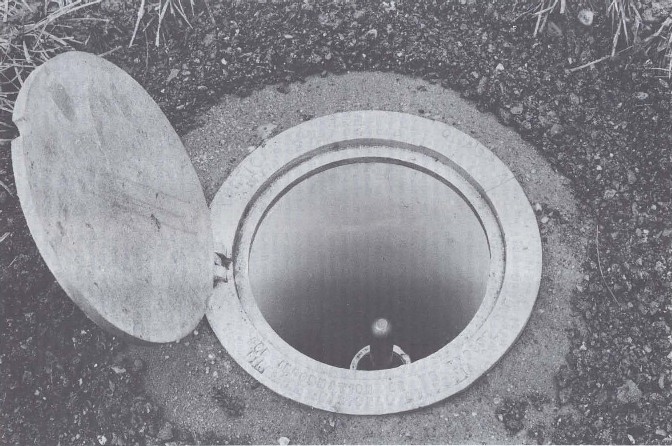

Figure 5.-Class A rod mark showing logo flange and hinged access cover.

17

1. Maneuver the drill into position with the rotary head situated over the spot where the

monument is to be placed. When the site is on

an incline, the vehicle should be facing uphill.

2. Level the vehicle with the stabilizing jacks. A

carpenter's level can be placed vertically against

the drill head mast to make sure it is

plumb both transversely and longitudinally.

3. Where neat landscaping must be preserved,

place a 2-meter square tarpaulin on the ground

and drill through a 1/2-meter hole cut in its

center.

4. Bore a hole 30 centimeters in diameter to a

depth slightly more than 1/2 meter for the

protective flanged encasement. This hole will

be filled with soil during subsequent operations,

but the objective is to loosen the soil in

preparation for setting the encasement.

5. Connect an appropriate bit to the first section

of a small diameter conventional flight auger

and begin drilling a hole to the required sleeve

depth. Depths for sleeves set within the continental

United States are specified in table 2

(page 27). Use figures 7 through 13 in conjunction

with this table to determine the depth.

Use the deepest depth indicated when a variety

of conditions exists. In regions outside the

conterminous States, the sleeve shall be placed

to a depth of 10 meters. Examples for determining

the depths are given in appendix E.

6. When the required depth is reached, pull the

augers straight up with no rotation to keep the

hole clean. Before removing the last section of

auger, clean the loose soil out and away from

the hole bored in step 4. After all the flights

have been retrieved, move the rotary drill head

off the axis of the hole to provide clearance for

the next steps.

7. Attach appropriate fittings to one end of a

2.54-centimeter (1-inch) PVC pipe to reduce

the inside diameter to 1.59 or 1.90 centimeters

(5/8 or 3/4 inch). Lower the pipe into the hole

with the reduced end down, then connect and

lower more sections of pipe as required. The

last section to be assembled must be cut to

length so that when the bottom of the hole is

reached, the top of the sleeve will be about 25

centimeters below the surface of the ground.

Finally, glue a female slip-to-thread adaptor to

the top of the sleeve. This will be used to make

connections to a grease pump for filling the

annular space with lubricant.

8. Assemble the 1.43-centimeter (9/16-inch)

stainless steel rod and lower it into the sleeve.

If a long, unwieldy length is required, the rod

may be coupled while it is being lowered into

the sleeve. To obtain tight joints, finger tighten

them and then apply one-quarter turn more.

9. When the rod assembly rests in the bottom of

the hole, it must be pressed or driven into the

soil beneath the sleeve. Alternately couple and

drive more sections of rod until it resists a

downward static force of 250 kilograms,7 but

make sure at least 1 meter of rod extends below